Polycarbonate Machine Grade

Machine-Grade Polycarbonate is a transparent, amorphous thermoplastic with excellent dimensional stability. It exhibits superior impact strength and rigidity over a wide range of service temperatures and is often used for structural applications where transparency and impact strength are essential—such as lenses, manifolds, site glasses and machine guards. Machine-Grade Polycarbonate suits a wide variety of electrical applications as well because of its high dielectric strength, low moisture absorption, excellent flammability rating and resistance to acid solutions. Machine-Grade polycarbonate is manufactured from FDA approved resin. The material has a 290°F (145°C) heat deflection temperature at 264 psi, absorbs very little moisture and resists acidic solutions. Good dielectric and thermal performance, excellent impact resistance, toughness, elongation and dimensional.These properties, in addition to good electrical characteristics, make machine grade polycarbonate stock shapes an excellent choice for electrical/electronic applications. Its strength, impact resistance and optical properties also make it an ideal material for certain structural applications that require visual translucency.

Polycarbonate - Machine Grade Plates Offer:

- Excellent Impact Resistance.

- Continuous Use Temperature to 290°F (145°C)

- Good Transparency (varies from grey tint to purple tint depending on resin used)

- Good Dielectric Properties

- Economical Thermal Performance

Polycarbonate (Lexan, Makrolon, Tecanat, Zelux, etc.) is a very durable material. The characteristics of polycarbonate are similar to those of polymethyl methacrylate (aka PMMA, acrylic, Lucite, etc.), but polycarbonate is stronger, usable in a wider temperature range and more expensive.

Flat sheets or plates of polycarbonate come in two different forms called sheet grade polycarbonate and machine grade polycarbonate.

The four biggest differences between the two forms of polycarbonate are:

- Sheet grade is extruded and not heat treated so it is unsuitable for most close tolerance machined parts. Machine grade is compression molded, or extruded, and then annealed via gradual heating and cooling to minimize internal stresses that are hugely problematic for machining.

- Sheet grade is readily available in window-clear sheet. Machine grade is not.

- Sheet grade is normally available up to 1/2" in thickness only. Machine grade is normally available only down to about 1/4" or 3/8" in thickness.

- Sheet grade is priced roughly 30% higher than sheet acrylic (aka PMMA and Lucite). Machine grade polycarbonate is priced roughly three to four times as high as sheet grade.

Sheet Grade Machine Grade

- Thickness Range 0.010"-0.5" 0.25"-6"

- Optical Clarity Yes No, except Zelux W

- Available Colors Clear, White, Black, Bronze, Gray Natural and Black

- Heat Annealed No Yes

HIGH IMPACT STRENGTH WITH HEAT RESISTANCE TO 250°F CONTINUOUS USE (120°C)

- Transparent

- Economical thermal performance

- Good dielectric properties

- Excellent impact resistance, toughness and elongation properties

MACHINE GRADE polycarbonate is stress relieved making it ideal for close tolerance machined parts. Quadrant stock shapes are produced from polycarbonate resins which meet the requirements of ASTM D 3935. It is machine grade, not optically clear. It can be both mechanically and vapor polished to improve optical clarity. Caution: During machining, never use coolants with an aromatic base.

Key Properties

Resistance to acid solutions

Economical thermal performance

Superior impact strength and rigidity

Transparency

Good dielectric properties

Standard Shapes and Forms

Sheet: .250” – 4” thick

Rod: .125” – 12” diameter

Tube: .375” - 8” OD / .250” - 7.75” ID

Other Forms: Film and profiles, Sheet – see Polycarbonate under Glazing and Construction Materials

The range of sizes and shapes are grade specific, order minimums may apply. Please contact us for more information.

Grades and Colors

Natural and black

20% Glass fiber reinforced (natural)

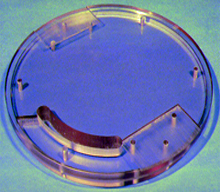

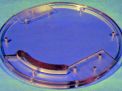

Polycarbonate Machine Grade Pictures

.jpg)

Get an instant offer on your damaged car

Get an offer instantly

Just tell us a bit about your car and boom, there's your offer.

Free pickup

You have seven days to accept our offer and schedule pickup.

Get paid on the spot

Our pickup partner will do a quick inspection, and hand you a check.