PFA (perfluoroalkoxy)

PFA (perfluoroalkoxy) has most of the physical and chemical properties of PTFE, but it has less permeation and more than 10 times the flex life. PFA also has outstanding crack and stress resistance and a low coefficient of friction. It can be used in environments where temperatures range from -320° F to 500° F. It also is suitable for hostile environments involving chemical, thermal and mechanical stress. PFA is used widely in the semiconductor industry where excellent electrical properties, high ionic purity and the ability to withstand a wide range of temperatures is essential. Typical applications include valve and pump linings, insulating bushings, nozzles, O-rings, gaskets and release operations. PFA also meets FDA specification 21CFR.177.1550 and is USP Class VI approved.

PFA is a high-performance, melt-processible, fluoropolymer that exhibits similar characteristics to PTFE. It performs exceedingly well in extreme thermal and chemical environments. PFA is a high-performance, melt-processible, fluoropolymer that exhibits similar characteristics to PTFE. Perfluoroalkoxy or PFA is a type of fluoro polymer with properties similar to poly tetra fluoro ethylene (PTFE). It differs from the PTFE resins in that it is melt-process able using conventional injection molding and screw extrusion techniques.PFA was invented by DuPont and is sold under the brand name Teflon PFA. Teflon is better known as the trade name for PTFE.

PFA is very similar in composition to the fluoro polymers PTFE and FEP (fluorinated ethylene-propylene). PFA and FEP both share PTFE's useful properties of low coefficient of friction and non-reactivity, but are more easily formable. PFA is softer than PTFE and melts at 305 °C. Another version of poly tetra fluoro ethylene perfluoro methyl vinyl ether, with a different ratio of PTFE and MVE monomers from PFA, is MFA.

PROPERTIES

PFA is similar to FEP in terms of its mechanical properties. These two are both superior to PTFE with regards to their flexibility, making them useful for tubing applications. However, their ability to endure repetitive folding (flex life) is actually lower than PTFEs own. PFA has a higher flex life than FEP.

PFA is preferable to FEP where heat is concerned, but PTFE itself is slightly more resistant to heat than both. PFA is more affected by water absorption and weathering than FEP, but is superior in terms of salt spray resistance. Perhaps the most impressive feature of PFA is its electrical properties, as it features the dielectric constant of PTFE, and an almost identical dissipation factor, but a dielectric strength that is around four times higher. ETFE is effectively a high strength engineering version of these three, and features what would likely be considered to be slightly degraded performance when compared with the other three.

APPLICATION

Due to its flexibility, extreme resistance to chemical attack and optical transparency, this material, along with FEP is routinely used for plastic labware and tubing that involves critical or highly corrosive processes. Nalgene is a well known laboratory supplier that makes extensive use of the two materials.

Another application is sheet linings for chemical equipment where fabric backed PFA sheets (SYMALIT PFA). The use of a PFA liner allows to replace expensive metals and alloys like Inconel or Hastelloy with lined carbon steel or lined fibre-reinforced plastic (FRP). Examples are SYMALIT PFA lined columns, scrubbers, reactors and pipes which stand harsh environments like concentrated HF and HCl and halogens.

Pump housings and pipe linings, Fluid handling or chemical processing equipment, Wet bench equipment, Tanks, Semiconductor wafer carriers, Hostile environments involving chemical, thermal and/or mechanical stress, Food processing and packaging equipment.

Advantages

Excellent chemical resistance

Good tribological properties

High heat resistance

Limitations

Cost

High processing temperature

Slow processing rates

Key Properties

Excellent chemical resistance

High flex life

Wide temperature range

Excellent electrical properties

Low coefficient of friction

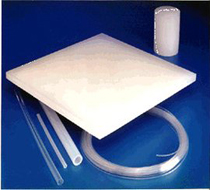

Standard Shapes and Forms

Sheet: .005” – 2.25” thick

Rod: .125” – 8” diameter

Other Forms: Flexible Tubing, Welding Rod and Roll Covers

PFA (perfluoroalkoxy) Pictures

Get an instant offer on your damaged car

Get an offer instantly

Just tell us a bit about your car and boom, there's your offer.

Free pickup

You have seven days to accept our offer and schedule pickup.

Get paid on the spot

Our pickup partner will do a quick inspection, and hand you a check.