Mykroy / Mycalex is a glass-bonded mica material. It is the most versatile and efficient electrical and thermal-insulating materials refined to meet the exacting demands of technical markets. Mykroy/Mycalex is the only mineral, fully inorganic material to bridge the performance gap between organic plastics and mineral ceramics. Mykroy/Mycalex material is a combination of finely powdered electrical quality glass and precisely defined and classified mica. The resulting stone-like, dense ceramic, inherits all the insulating advantages of both components. It can be machined to close tolerances or transfer molded into intricate shapes with or without metal inserts. Mykroy/Mycalex is impervious to moisture and does not outgas under high temperature or in vacuum environments. It has exceptional dimensional stability even at high temperature. It does not burn or carbonize and has an unlimited shelf life.

Mykroy/Mycalex Ceramoplastic materials are one of today's most versatile and efficient insulating materials perfected to meet the exacting demands of technical markets, worldwide. Glass-Bonded Mica is the only inorganic material to bridge the performance materials gap between organic plastics and ceramics.

Mykroy/Mycalex's unique high performance technical ceramic is a union of finely powered electrical quality glass and precisely defined and classified mica. The union of mica and glass takes place under simultaneous pressure and heat, transforming the materials into a new composition that inherits all the insulating advantages of both constituents.

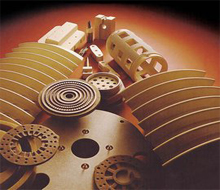

Mykroy/Mycalex materials are available in sheet, rod, and custom fabricated/molded configurations.

Mykroy/Mycalex is the trade name for the glass bonded mica ceramic material produced by Crystex Composites LLC. Since 1919, Mykroy/Mycalex remains the most versatile and efficient electrical and thermal insulating material produced to meet the exacting demands of technical markets. Mykroy/Mycalex is the only fully inorganic material to bridge the performance gap between high performance plastics and structural ceramics. Mykroy/Mycalex glass bonded mica ceramic is a simultaneous union under high pressure and temperature of finely powdered electrical quality glass and precisely defined (natural or synthetic) mica. The resulting stone-like, dense ceramic material inherits all of the insulating advantages of both components.

Mykroy/Mycalex is available in machinable grades suitable for processing with standard carbide tools and water (or a water based lubricant) and in moldable grades that do not require firing or sintering after molding. As a result, the material can accommodate metal inserts during molding similar to thermoplastics. Mykroy/Mycalex does not burn or outgas. The material is dimensionally stable at temperatures ranging from -240°C to 800°C.

Advantages of Mykroy/Mycalex

Applications

Surgical device insulator, vacuum components in CVD and plasma chambers, hightemperature thermal and electrical insulators, corona treating insulator, highintensity light focusing structures, plastic and rubber sealing jawsetc…Everything from glass handling to the national defense.

Mycalex Mica-filled ceramic

Mycalex Mica-filled ceramics are available in 4 standard grades:

MM400 - Dark Grey -Max temp 750 F - 2.5 density

MM500 - Light Grey - Max Temp 750 F - 2.7 density

MM1100 - Cream Colored - Max Temp 1100 F - 2.8 density

MM1600 (new !!) - Max Temp 1600 F

Mykroy/Mycalex 1600 is a compression molded glass mica composite that is the perfect alternative to high performance plastics where high temperature, good dielectric strength and good arc resistance are required. This material is softer than other high temperature machinable ceramics allowing for the fabrication of intricate or complex shapes. It can be drilled or tapped and can accommodate helical inserts. In addition, no post firing is required after fabrication.

Mykroy/Mycalex Ceramoplastic materials are one of today's most versatile and efficient insulating materials. Glass-Bonded Mica is the only inorganic material to bridge the performance materials gap between organic plastics and ceramics.

Mykroy/Mycalex's unique high performance technical ceramic is a union of finely powered electrical quality glass and precisely defined and classified mica. The union of mica and glass takes place under simultaneous pressure and heat, transforming the materials into a new composition that inherits all the insulating advantages of both constituents.

Mykroy/Mycalex materials have continuous operating temperature ranges of -459 degrees F to +1300 degrees F. They are produced in sheet and rod form as well as machined parts to meet specific customer specifications. They are also moldable, like plastic, and can even accept metal inserts during molding.

Mykroy / Mycalex Pictures